A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). Unlike hydraulic pumps that convert mechanical energy into hydraulic energy, a hydraulic motor operates in the reverse, making it an essential component in countless industrial applications.

From heavy machinery and construction equipment to manufacturing systems and aerospace applications, the hydraulic motor provides efficient power transmission with exceptional power-to-weight ratios. This guide explores the fundamental aspects of these remarkable devices, from their structural characteristics to proper maintenance procedures.

The global hydraulic motor market is projected to grow significantly in the coming years, driven by increasing demand from construction, agriculture, and mining sectors where reliable power transmission is critical.

1. Hydraulic Motor Structural Features, Principles & Performance Parameters

Understanding the design characteristics and operational principles of different hydraulic motors—including hydraulic motor types—is essential for selecting the right component for specific applications and ensuring optimal performance.

Common Hydraulic Motor Types and Their Structural Features

Gear Motors

Gear motors are the most common and economical type of hydraulic motor. They operate on the same principle as gear pumps but in reverse. These motors consist of two meshing gears - a driven gear and an idler gear - within a housing.

As hydraulic fluid is forced into the inlet port, it flows between the gear teeth and the housing, creating pressure that causes the gears to rotate. The fluid is then discharged through the outlet port as the gears mesh together, forcing the fluid out.

- Simple design with few moving parts

- Compact size and light weight

- High tolerance for contamination

- Generally lower efficiency (70-85%) compared to other types

- Available in both external and internal gear configurations

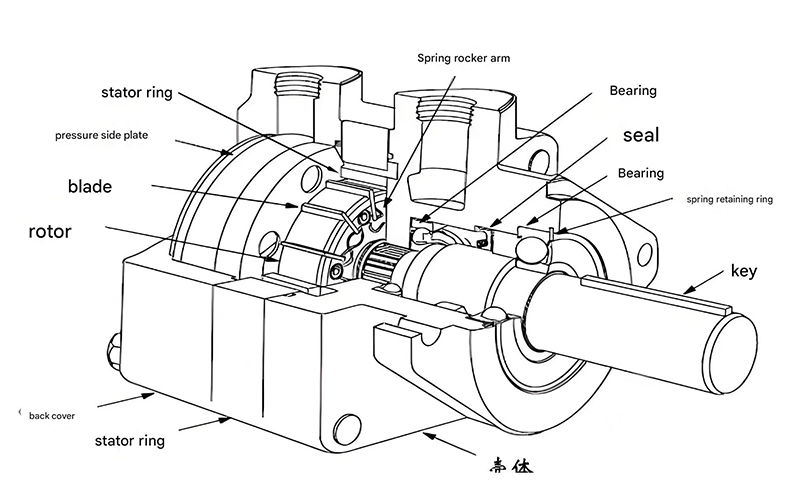

Vane Motors

Vane motors feature a cylindrical rotor with radial slots that house vanes, rotating within an eccentric cam ring. The vanes are pushed outward by centrifugal force and/or spring pressure to maintain contact with the cam ring.

When pressurized fluid enters the inlet, it acts on the vanes, creating an imbalance of forces that causes the rotor to rotate. The vane design allows for smoother operation than gear motors, making them suitable for applications requiring more precise speed control.

- Moderate efficiency (80-90%)

- Smooth operation at moderate speeds

- Good speed control capabilities

- More sensitive to fluid contamination than gear motors

- Available in fixed and variable displacement models

Piston Motors

Piston motors are the most efficient and powerful type of hydraulic motor, utilizing a series of pistons reciprocating within a cylinder block. They are available in both axial and radial piston configurations, with axial being more common in industrial applications.

In axial piston motors, pistons arranged parallel to the drive shaft move in and out of their cylinders as the swash plate or bent axis changes their angle relative to the cylinder block. This motion converts fluid pressure into rotational force.

- Highest efficiency (85-95%) among hydraulic motors

- Capable of high pressures and torque output

- Precise control at both high and low speeds

- More complex design requiring cleaner fluid

- Available in fixed and variable displacement options

Gerotor Motors

Gerotor motors feature an inner rotor with external teeth and an outer rotor with internal teeth, where the outer rotor has one more tooth than the inner rotor. This design creates expanding and contracting chambers as the rotors rotate.

When hydraulic fluid enters the motor, it fills the expanding chambers, creating pressure that causes the inner rotor to rotate relative to the outer rotor. The fluid is then discharged through the outlet as the chambers contract.

- Compact design with high power density

- Smooth operation at low speeds

- Moderate efficiency (75-85%)

- Good for applications requiring high torque in limited space

- Generally lower cost than piston motors

Hydraulic Motor Working Principles

All hydraulic motor designs operate on the same fundamental principle: converting fluid pressure into mechanical rotation through the application of force on surfaces within the motor. This process can be broken down into several key stages:

Fluid Entry & Pressure Application

Pressurized hydraulic fluid enters the motor through the inlet port, directed to specific chambers or areas within the motor design. The fluid pressure acts uniformly on all surfaces it contacts.

Force Generation

The pressure creates a force on the motor's internal components (gears, vanes, or pistons) according to the formula: Force = Pressure × Area. This force is what drives the motor's rotation.

Mechanical Conversion

The linear force acting on the motor's components is converted into rotational motion through the motor's design, whether through meshing gears, eccentric cam rings, or angled swash plates.

Fluid Discharge

After acting on the motor's components, the fluid is discharged through the outlet port at lower pressure, returning to the hydraulic reservoir to be recirculated through the system.

Key Physics Behind Hydraulic Motor Operation

The operation of a hydraulic motor relies on Pascal's Law, which states that pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid. This principle allows hydraulic systems to transmit force and power efficiently over distance.

The relationship between flow rate and speed, and between pressure and torque, are fundamental to hydraulic motor performance. Generally, motor speed is proportional to flow rate, while torque output is proportional to pressure.

Hydraulic Motor Performance Parameters

Understanding the key performance parameters of a hydraulic motor is essential for proper selection, system design, and performance evaluation. These parameters define the motor's capabilities and limitations in specific applications.

| Parameter | Description | Typical Units |

|---|---|---|

| Displacement | The volume of fluid required to rotate the motor output shaft one full revolution | cm³/rev, in³/rev |

| Pressure Rating | Maximum operating pressure the motor can sustain without damage | bar, psi |

| Speed Range | Minimum and maximum rotational speed the motor can effectively operate within | RPM |

| Torque Output | The rotational force the motor can produce at various pressure levels | N·m, lb·ft |

| Power Output | The rate at which the motor can do work, calculated from torque and speed | kW, hp |

| Efficiency | Ratio of output power to input power, including volumetric and mechanical efficiency | % |

| Flow Rate | Volume of fluid passing through the motor per unit time, determining speed | L/min, GPM |

| Temperature Range | Ambient and fluid temperature range within which the motor operates correctly | °C, °F |

Performance Comparison Chart

Torque Calculation Formula

Torque (N·m) = (Pressure (bar) × Displacement (cm³/rev)) / (20 × π)

This formula shows the direct relationship between pressure, displacement, and the torque output of a hydraulic motor.

Speed Calculation Formula

Speed (RPM) = (Flow Rate (L/min) × 1000) / Displacement (cm³/rev)

This formula demonstrates how the motor's speed is determined by flow rate and displacement.

2. Hydraulic Motor Usage & Maintenance

Proper installation, operation, and maintenance are critical to maximizing the service life, efficiency, and reliability of any hydraulic motor system. Neglecting these aspects can lead to premature failure and increased operational costs.

Proper Hydraulic Motor Installation Procedures

Correct installation of a hydraulic motor is the foundation for reliable operation. Improper mounting can lead to misalignment, excessive vibration, and premature wear of both the motor and connected components.

Mounting Surface Preparation

- Ensure mounting surface is clean and flat

- Remove all burrs, paint, and debris

- Check surface flatness with a straightedge

- Use proper gaskets or O-rings as specified

Shaft Alignment

- Achieve precise alignment with driven equipment

- Use dial indicators for accurate measurement

- Limit angular misalignment to 0.1° maximum

- Limit parallel misalignment to 0.1mm/m maximum

Fastening Requirements

- Use specified bolt grades and sizes

- Tighten to recommended torque values

- Apply even pressure across mounting flange

- Consider using lock washers or thread locker

Hydraulic Connections

Proper fluid connections are essential for preventing leaks and ensuring efficient operation of the hydraulic motor:

- Identify correct ports (usually marked "P" for pressure, "T" for return)

- Clean all connection threads before assembly

- Use proper sealing methods (O-rings, thread sealant as recommended)

- Torque fittings to manufacturer specifications

- Ensure hoses and lines are properly supported and not kinked

- Route lines to avoid excessive bending or tension

System Priming & Initial Start-Up

Before putting the hydraulic motor into full operation, proper priming and start-up procedures are critical:

- Fill hydraulic reservoir to proper level with recommended fluid

- Open all bleed valves to remove air from the system

- Manually rotate motor shaft if possible to help purge air

- Start system at low pressure and allow fluid to circulate

- Check for leaks at all connections

- Gradually increase pressure to operating levels

- Monitor for unusual noise or vibration during initial operation

Improper alignment is one of the leading causes of premature hydraulic motor failure. Even minor misalignment can cause excessive bearing loads, shaft stress, and increased wear rates.

Hydraulic Motor Operation Best Practices

Proper operation of equipment containing a hydraulic motor is essential for achieving optimal performance and extending service life. Operators should be trained on both the equipment and the underlying hydraulic principles.

Operating Limits and Parameters

- Never exceed the manufacturer's recommended pressure ratings for the hydraulic motor

- Operate within specified speed ranges to prevent overheating and damage

- Maintain proper fluid temperature (typically 100-140°F / 38-60°C)

- Monitor pressure gauges regularly during operation

- Avoid sudden pressure spikes by operating controls smoothly

Operational Monitoring

- Listen for unusual noises (knocking, whining, or grinding) that may indicate hydraulic motor issues

- Watch for excessive vibration during operation

- Check for external leaks around motor connections

- Monitor fluid levels and condition regularly

- Keep records of operating hours for maintenance scheduling

Starting and Stopping Procedures

Proper Start-Up Sequence

- Check fluid level in reservoir

- Verify all system valves are in correct position

- Start prime mover (engine or electric motor) at low idle

- Allow system pressure to build gradually

- Operate hydraulic motor at low speed initially

- Check for proper operation before full load

Recommended Shutdown Sequence

- Reduce hydraulic motor speed to minimum

- Relieve system pressure gradually

- Place all controls in neutral position

- Shut down prime mover

- Visually inspect motor and connections

- Record any issues observed during operation

Preventing Common Operational Issues

Many hydraulic motor problems can be prevented through proper operational practices:

- Avoid overrunning loads that can cause motor cavitation

- Use proper counterbalance valves for vertical loads

- Allow adequate warm-up time in cold environments

- Implement proper system filtration to protect the hydraulic motor from contamination

- Use only recommended hydraulic fluids and additives

- Address minor leaks immediately before they become major problems

- Provide adequate ventilation for heat dissipation

Hydraulic Motor Maintenance Procedures

Regular maintenance is essential for maximizing the service life and performance of a hydraulic motor. A well-executed maintenance program can prevent unexpected failures and reduce overall operating costs.

Preventive Maintenance Schedule

| Maintenance Task | Daily | Weekly | Monthly | Quarterly | Annual |

|---|---|---|---|---|---|

| Fluid level check | |||||

| Visual leak inspection | |||||

| Fluid temperature check | |||||

| Filter inspection | |||||

| Fluid condition check | |||||

| Bolt torque verification | |||||

| Filter replacement | |||||

| Fluid analysis | |||||

| Motor disassembly inspection |

Fluid Maintenance

Proper fluid maintenance is critical for hydraulic motor performance and longevity:

- Use only manufacturer-recommended hydraulic fluids

- Maintain proper fluid levels to prevent cavitation

- Change fluid according to schedule or condition

- Filter fluid when adding to system

- Monitor fluid for contamination, discoloration, or foaming

- Check for proper viscosity, especially in temperature extremes

Note: Contaminated fluid is responsible for over 70% of hydraulic motor failures. Implementing a robust filtration program can significantly extend motor life.

Seal and Gasket Maintenance

Seals and gaskets prevent fluid leakage and contamination ingress:

- Inspect all seals regularly for signs of wear or damage

- Replace seals at first sign of leakage

- Use proper seal installation tools to prevent damage

- Ensure replacement seals are correct for the application

- Consider periodic seal replacement as preventive maintenance

- Use compatible seal materials for the hydraulic fluid

Note: Early detection of seal degradation can prevent costly fluid loss and contamination that can damage the hydraulic motor internals.

Lubrication Requirements

While the hydraulic fluid provides internal lubrication, many hydraulic motor designs have external components that require separate lubrication:

- Check manufacturer specifications for lubrication points and intervals

- Use only recommended lubricants for bearing housings and shafts

- Maintain proper lubricant levels in sealed bearing compartments

- Clean lubrication points before applying fresh lubricant

- Remove old grease completely when relubricating fittings

- Document all lubrication activities in maintenance records

- Adjust lubrication frequency for extreme operating conditions

Hydraulic Motor Troubleshooting & Repair

Even with proper maintenance, hydraulic motor issues can arise. Effective troubleshooting requires systematic diagnosis to identify root causes before attempting repairs.

Common Hydraulic Motor Problems and Solutions

Motor fails to rotate or rotates slowly

Possible causes:

- Insufficient flow or pressure to the motor

- Contaminated fluid causing valve blockage

- Mechanical binding or excessive load

- Internal motor damage (worn or broken components)

- Inlet line restriction or cavitation

Recommended solutions:

- Check system pressure and flow rates

- Inspect and replace filters; analyze fluid condition

- Verify load conditions and alignment

- Disassemble motor for internal inspection if necessary

- Check for kinks or restrictions in supply lines

Excessive noise during operation

Possible causes:

- Cavitation due to insufficient fluid supply

- Aeration (air in hydraulic fluid)

- Misalignment between motor and driven equipment

- Worn bearings or internal components

- Excessive pressure or pressure spikes

Recommended solutions:

- Check reservoir level and inlet line for restrictions

- Bleed system and check for suction line leaks

- Realign motor and driven equipment

- Inspect motor internals and replace worn parts

- Check pressure relief valves and reduce system pressure if necessary

Leakage from motor

Possible causes:

- Worn or damaged shaft seals

- Loose or damaged connection fittings

- Cracked housing due to excessive pressure or impact

- Failed O-rings or gaskets

- Excessive internal pressure

Recommended solutions:

- Replace shaft seals with proper type and size

- Tighten or replace fittings as needed

- Inspect housing for damage; replace if cracked

- Replace all O-rings and gaskets with compatible materials

- Check for pressure relief valve malfunction

Motor overheating

Possible causes:

- Excessive pressure drop across the motor

- Inadequate fluid flow or cooling

- Contaminated fluid causing increased friction

- Mechanical binding or misalignment

- Operating beyond rated capacity

Recommended solutions:

- Check system pressure settings and adjust if necessary

- Verify flow rates and ensure cooling system is functioning

- Replace fluid and filters; clean system if necessary

- Check alignment and bearing condition

- Reduce load or upgrade to appropriately sized motor

Disassembly and Inspection Procedures

When internal inspection of a hydraulic motor is necessary, follow these procedures:

- Relieve all pressure from the hydraulic system

- Disconnect hydraulic lines and plug them to prevent contamination

- Remove motor from mounting and driven equipment

- Document orientation of components during disassembly

- Clean external surfaces thoroughly before opening

- Disassemble in systematic manner, keeping parts organized

- Inspect all components for wear, scoring, or damage

- Measure critical dimensions against specifications

- Check bearing clearance and condition

- Replace all seals, O-rings, and wear components

Reassembly and Testing Guidelines

Proper reassembly is critical for hydraulic motor performance after inspection or repair:

- Clean all reusable components thoroughly

- Lubricate internal parts with clean hydraulic fluid during assembly

- Install new seals and gaskets according to specifications

- Follow proper torque specifications for all fasteners

- Reassemble in reverse order of disassembly

- Verify proper rotation and freedom of movement

- Reinstall motor using proper alignment procedures

- Connect hydraulic lines correctly

- Prime and test at low pressure initially

- Gradually increase pressure and monitor for proper operation

Repair vs. Replacement Decision Guidelines

When a hydraulic motor fails, consider these factors when deciding between repair and replacement:

Consider Repair When:

- Motor is relatively new or low-hour

- Damage is limited to specific replaceable components

- Replacement cost is significantly higher than repair

- Lead time for new motor would cause excessive downtime

- Motor is a special or hard-to-obtain model

Consider Replacement When:

- Motor has high operating hours (approaching end of service life)

- Severe housing or major component damage exists

- Repair cost exceeds 50-60% of replacement cost

- Efficiency has significantly degraded

- Newer models offer improved efficiency or features

- Motor is obsolete with limited parts availability

Maximizing Hydraulic Motor Performance and Longevity

A hydraulic motor represents a significant investment that can provide years of reliable service when properly selected, installed, operated, and maintained. By understanding the structural characteristics, operating principles, and performance parameters of your specific motor type, you can optimize its operation within your hydraulic system.

Implementing a comprehensive maintenance program that includes regular inspections, fluid analysis, and component replacement as needed will help prevent unexpected failures and costly downtime. When issues do arise, systematic troubleshooting will help identify root causes and guide appropriate repair or replacement decisions.

Remember that each hydraulic motor application has unique requirements, and consulting with manufacturers or hydraulic system specialists can provide valuable insights for your specific operating conditions. With proper care and attention, your hydraulic motor will deliver efficient, reliable performance for its intended service life.