Fundamentals of Fluid and Hydraulics

A comprehensive guide to hydraulic fluid mechanics, covering viscosity, kinematics, statics, dynamics, pipe flow, and orifice flow.

1. Hydraulic Fluid Viscosity and Specific Heat

Viscosity is a fundamental property of hydraulic fluids that measures their resistance to flow. In fluid and hydraulics systems, understanding viscosity is critical for designing efficient components and predicting performance.

Newtonian vs. Non-Newtonian Fluids

Newtonian fluids, such as mineral oils, exhibit a linear relationship between shear stress and shear rate. Non-Newtonian fluids, like some synthetic lubricants, have a nonlinear relationship.

The viscosity of a fluid and hydraulics system is influenced by temperature and pressure. As temperature increases, viscosity typically decreases, while pressure increases generally lead to higher viscosity.

Viscosity Index (VI)

The viscosity index is a measure of how much a fluid's viscosity changes with temperature. A higher VI indicates less viscosity change:

| Fluid Type | Viscosity Index (VI) |

|---|---|

| Mineral Oil | 90-100 |

| High VI Mineral Oil | 100-120 |

| Synthetic Oil | 130-170 |

Specific heat is another critical property in fluid and hydraulics systems. It is the amount of heat required to raise the temperature of a unit mass of fluid by one degree. In hydraulic systems, fluids with high specific heat are preferred as they can absorb more heat without significant temperature rise.

Key Formulas

Dynamic Viscosity (μ): τ = μ * (du/dy)

Kinematic Viscosity (ν): ν = μ/ρ

Specific Heat (c): Q = mcΔT

Practical Application

In hydraulic systems, maintaining proper viscosity is essential. Too high viscosity increases energy consumption, while too low viscosity can cause wear due to insufficient lubrication. For example, in cold environments, a fluid with a high VI or a synthetic fluid might be selected to ensure adequate viscosity.

Section Contents

- Viscosity Definition

- Temperature & Pressure Effects

- Viscosity Measurement

- Specific Heat Capacity

- Applications in Fluid & Hydraulics

Related Resources

Quick Reference

Dynamic Viscosity Units:

- • Pascal-second (Pa·s)

- • Poise (P)

- • Centipoise (cP)

Kinematic Viscosity Units:

- • Square meter per second (m²/s)

- • Stokes (St)

- • Centistokes (cSt)

2. Fluid Kinematics Fundamentals

hydraulic scientific principles:Fluid kinematics is the study of fluid motion without considering the forces that cause the motion. In fluid and hydraulics, this involves analyzing velocity, acceleration, and flow patterns of fluids.

Lagrangian vs. Eulerian Approach

In the Lagrangian approach, we track individual fluid particles. In the Eulerian approach, we analyze the flow at fixed points in space.

Types of Fluid Flow

- Steady vs. Unsteady Flow: Flow parameters do not change with time in steady flow.

- Uniform vs. Non-Uniform Flow: Flow parameters do not change with position in uniform flow.

- Laminar vs. Turbulent Flow: Laminar flow is smooth, while turbulent flow is chaotic.

Velocity and Acceleration Fields

In fluid and hydraulics, the velocity field is a vector field that describes the velocity of a fluid at every point in space and time:

V(x, y, z, t) = u(x, y, z, t)i + v(x, y, z, t)j + w(x, y, z, t)k

The acceleration of a fluid particle is given by:

a = ∂V/∂t + (V·∇)V

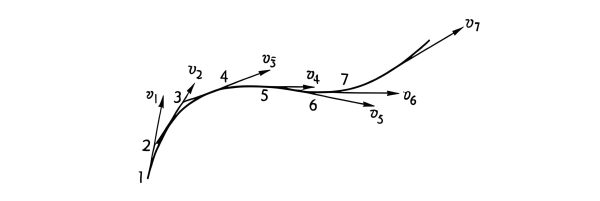

Streamlines, Pathlines, and Streaklines

These are important concepts for visualizing fluid flow:

Streamlines

Tangent to the velocity vector at every point. Instantaneous flow direction.

Pathlines

Path followed by individual fluid particles over time.

Streaklines

Locus of all particles that have passed through a fixed point.

Continuity Equation

The continuity equation is a statement of conservation of mass for fluid flow. For incompressible fluids, it simplifies to:

∇·V = 0

or in Cartesian coordinates:

∂u/∂x + ∂v/∂y + ∂w/∂z = 0

For a control volume:

∂ρ/∂t + ∇·(ρV) = 0

where ρ is density, V is velocity vector.

Practical Application

In hydraulic systems, understanding fluid kinematics helps in designing efficient pipelines and components. For example, analyzing flow patterns around valves and pumps ensures minimal energy losses and prevents cavitation.

3. Fluid Statics

Fluid statics deals with fluids at rest and the hydraulic pressure distribution within the fluid. In fluid and hydraulics, this is crucial for understanding forces on submerged surfaces and in hydraulic systems.

Hydrostatic Pressure

The pressure in a fluid at rest increases with depth due to the weight of the fluid above. The hydrostatic pressure is given by:

p = p₀ + ρgh

where p₀ is the pressure at the surface, ρ is fluid density, g is acceleration due to gravity, and h is depth.

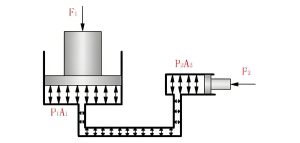

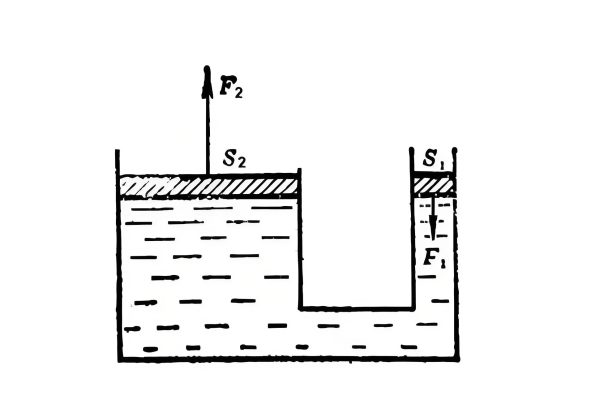

Pascal's Law

Pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

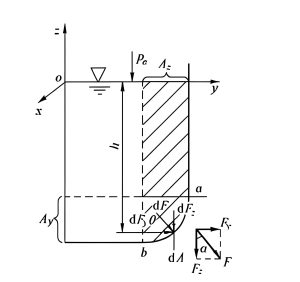

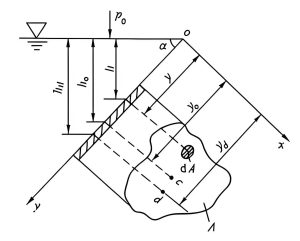

Forces on Submerged Surfaces

In fluid and hydraulics, calculating forces on submerged surfaces is important for designing dams, gates, and other structures. The resultant hydrostatic force on a plane surface is:

F = ρgȳA

where ȳ is the distance from the fluid surface to the centroid of the area A.

Horizontal Surface

The force is uniform and acts at the centroid of the surface.

Vertical Surface

The force increases with depth and acts below the centroid.

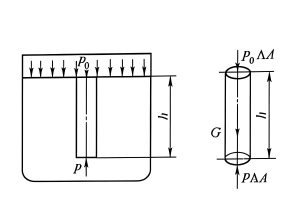

Buoyancy and Archimedes' Principle

Archimedes' principle states that the buoyant force acting on a body immersed in a fluid is equal to the weight of the fluid displaced by the body:

F_buoyancy = ρgV

where V is the volume of fluid displaced.

Stability of Floating Bodies

For a floating body to be stable, the metacenter (M) must be above the center of gravity (G):

Manometry

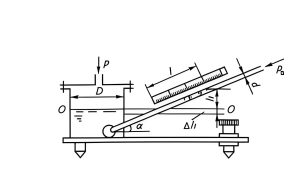

Manometers are devices used to measure pressure in fluid and hydraulics systems. Common types include:

U-Tube Manometer

Measures pressure difference using a U-shaped tube filled with a liquid.

Inclined Manometer

Increases sensitivity by using an inclined tube.

Differential Manometer

Measures the difference between two pressures.

Practical Application

In hydraulic lifts and presses, Pascal's law is used to multiply force. A small force applied to a small piston creates a pressure that is transmitted to a larger piston, resulting in a larger force. This principle is fundamental in fluid and hydraulics applications.

4. Fluid Dynamics

How do hydraulics work. Fluid dynamics studies the behavior of fluids in motion and the forces acting on them. In fluid and hydraulics, this is essential for analyzing pumps, turbines, and flow in pipes.

Bernoulli's Equation

For steady, incompressible, inviscid flow along a streamline, Bernoulli's equation states:

p + ½ρv² + ρgh = constant

where p is pressure, ρ is density, v is velocity, g is gravity, and h is height.

Navier-Stokes Equations

The Navier-Stokes equations describe the motion of viscous fluid substances and are fundamental in fluid and hydraulics:

ρ(∂v/∂t + v·∇v) = -∇p + μ∇²v + ρg

where μ is dynamic viscosity.

Momentum Equation

The momentum equation is a statement of Newton's second law and is crucial for analyzing forces in fluid and hydraulics systems:

ΣF = ∂/∂t ∫_CV ρv dV + ∫_CS ρv(v·n) dA

For steady flow with one inlet and one outlet:

F = ρQ(V_out - V_in)

Dimensional Analysis and Similarity

In fluid and hydraulics, dimensional analysis helps in reducing the number of variables and ensuring similarity between model and prototype:

Reynolds Number (Re)

Ratio of inertial forces to viscous forces:

Re = ρvL/μ

Froude Number (Fr)

Ratio of inertial forces to gravitational forces:

Fr = v/√(gL)

Mach Number (Ma)

Ratio of flow velocity to the speed of sound:

Ma = v/c

Flow Measurement

Common methods for measuring flow rate in fluid and hydraulics systems include:

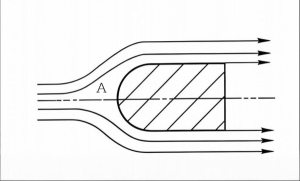

Venturi Meter

Uses pressure difference across a constriction:

Orifice Plate

Measures flow by creating a pressure drop:

Rotameter

Variable area flow meter with a float:

Practical Application

In fluid and hydraulics systems, pumps and turbines are designed using principles of fluid dynamics. For example, centrifugal pumps use rotational energy from an impeller to increase the pressure and flow rate of a fluid.

5. Fluid Flow in Pipelines

Hydraulic Flow Control valveUnderstanding fluid flow in pipelines is critical in fluid and hydraulics for designing efficient distribution systems and minimizing energy losses.

Laminar vs. Turbulent Flow

The flow regime in pipes depends on the Reynolds number:

- • Laminar flow: Re < 2000

- • Transitional flow: 2000 < Re < 4000

- • Turbulent flow: Re > 4000

Head Loss in Pipes

Head loss in pipes is due to friction and minor losses from fittings:

h_L = f (L/D) (v²/2g)

where f is the friction factor, L is pipe length, D is diameter, v is velocity, and g is gravity.

Friction Factor Calculation

The friction factor depends on the flow regime and pipe roughness:

Laminar Flow

For laminar flow, the friction factor is:

f = 64/Re

Turbulent Flow

For turbulent flow, use the Colebrook equation:

1/√f = -2 log₁₀[(ε/D)/3.7 + 2.51/(Re√f)]

where ε is pipe roughness.

Moody Chart for Friction Factor Determination

Minor Losses

Minor losses occur due to fittings, valves, bends, and contractions/expansions:

h_L = K (v²/2g)

where K is the loss coefficient specific to the fitting.

| Fitting | Loss Coefficient (K) |

|---|---|

| Globe Valve (fully open) | 10.0 |

| Gate Valve (fully open) | 0.19 |

| 90° Elbow (standard) | 0.9 |

| Sudden Expansion | (1 - A₁/A₂)² |

Pump Power Requirements

In fluid and hydraulics systems, pumps are used to overcome head losses and provide the required flow rate. The power required is:

P = ρgQH/η

where Q is flow rate, H is total head, and η is pump efficiency.

Net Positive Suction Head (NPSH)

To prevent cavitation, the available NPSH must be greater than the required NPSH:

NPSH = (p₁/ρg) + (v₁²/2g) - p_v/ρg

where p_v is the vapor pressure of the fluid.

Practical Application

In industrial fluid and hydraulics systems, proper pipe sizing and material selection are crucial to minimize energy losses. For example, using smooth pipes and minimizing the number of fittings can reduce head losses and lower pumping costs.

6. Orifice Flow and Gap Flow

Hydraulic Flow Meter: Orifice and gap flows are common in fluid and hydraulics systems, used for flow control, measurement, and leakage analysis.

Orifice Flow

Flow through an orifice is governed by:

Q = C_d A √(2Δp/ρ)

where C_d is the discharge coefficient, A is orifice area, and Δp is pressure difference.

Discharge Coefficient

The discharge coefficient accounts for non-ideal flow effects:

- • For sharp-edged orifices: C_d ≈ 0.61

- • For rounded orifices: C_d ≈ 0.97

- • Depends on Reynolds number and orifice geometry

Types of Orifices

Orifices are classified based on their shape and edge characteristics:

Sharp-Edged Orifice

Has a sharp edge to minimize contact with the fluid:

Round-Edged Orifice

Smoother entry reduces turbulence:

Bevelled Orifice

Used to control the direction of flow:

Flow Through Gaps

Flow through gaps (such as between pistons and cylinders) is important for leakage analysis in fluid and hydraulics systems:

Parallel Plate Gap

Flow rate for laminar flow between parallel plates:

Q = (bh³Δp)/(12μL)

where b is width, h is gap height, L is length.