Hydraulic Oil Maintenance Excellence

A comprehensive guide to maximizing performance, extending lifespan, and ensuring safety through proper management of hydraulic oil in industrial systems.

Effective management of hydraulic oil—especially tractor hydraulic oil, a specialized variant for agricultural tractor systems—is fundamental to the reliability and efficiency of any hydraulic system. The proper selection, application, and monitoring of hydraulic oil directly impact equipment performance, maintenance costs, and operational safety.

Selection Criteria for Hydraulic Oil

Choosing the right hydraulic oil requires careful consideration of several critical factors. The viscosity grade is paramount, as it must match the system's operating temperature range. Hydraulic systems operating in extreme cold require lower viscosity hydraulic oil to ensure proper flow during startup, while high-temperature applications demand higher viscosity grades to maintain adequate film strength.

Other important characteristics include viscosity index, oxidation resistance, shear stability, and additive packages. Anti-wear additives are essential in most industrial applications to protect components from metal-to-metal contact. For systems operating in environmentally sensitive areas, environmentally friendly hydraulic oil formulations that meet biodegradability standards should be selected.

Storage and Handling Procedures

Proper storage of hydraulic oil is crucial to prevent contamination before it even enters the system. Hydraulic oil should be stored in a clean, dry environment with controlled temperature. Drums should be placed horizontally on racks to keep the bung holes in the proper position, and the area should be free from dust, moisture, and chemical fumes that could compromise the oil's integrity.

When handling hydraulic oil, always use clean, dedicated equipment for transfer. Funnels, pumps, and hoses should be thoroughly cleaned before each use to prevent cross-contamination between different types of hydraulic oil or between new and used oil. It's also essential to avoid prolonged exposure of hydraulic oil to air, as this can promote oxidation and moisture absorption.

System Filling and Initial Charging

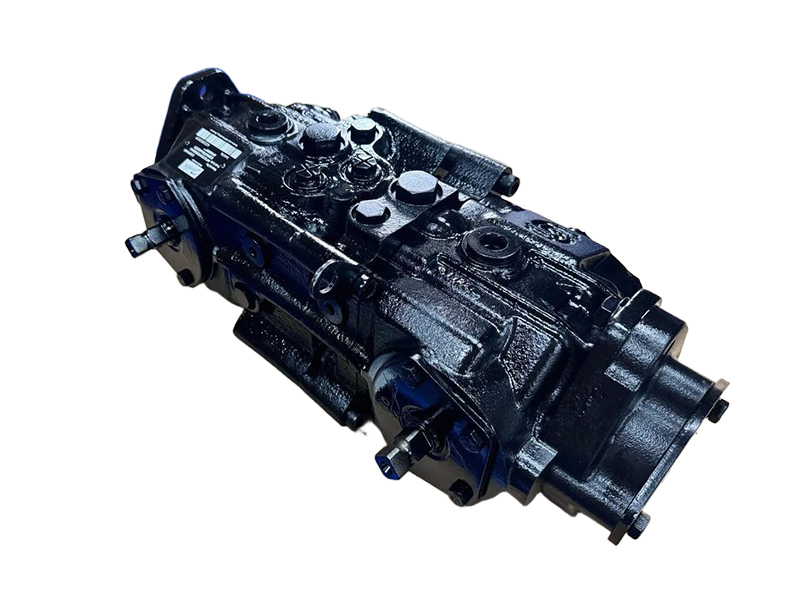

The process of filling a hydraulic system with new hydraulic oil requires meticulous attention to detail. Before adding any hydraulic oil, ensure the system is clean and free from debris left during manufacturing or maintenance. Flushing the system with a dedicated flushing fluid may be necessary for new installations or after major component replacement.

When adding hydraulic oil, use a filtration system with appropriate micron rating to remove any potential contaminants. Fill the reservoir to the recommended level, allowing for thermal expansion. After initial filling, circulate the hydraulic oil through the system without applying load to remove any entrained air, which can cause cavitation and reduced system performance.

Operating Parameters Monitoring

Maintaining optimal operating conditions is key to extending the service life of hydraulic oil. Regular monitoring of system temperature is critical, as excessive heat accelerates hydraulic oil degradation. Most hydraulic systems are designed to operate within a specific temperature range, typically between 40°C and 60°C (104°F and 140°F).

Pressure levels should also be monitored to ensure they remain within the system's design specifications. Excessive pressure can lead to increased stress on components and higher operating temperatures, both of which negatively impact hydraulic oil performance. Implementing a scheduled monitoring program that includes regular oil sampling allows for early detection of potential issues before they escalate into major problems.

Replacement Schedules and Procedures

Establishing a proper replacement schedule for hydraulic oil is essential, but it should be based on actual oil condition rather than just elapsed time. While manufacturers often provide recommended intervals, these should be adjusted based on operating conditions, oil analysis results, and system performance.

When replacing hydraulic oil, it's important to drain the system completely, including all reservoirs, lines, and components where old oil might be trapped. After draining, clean the reservoir thoroughly to remove sludge, sediment, and other contaminants. Replace all filters as part of the oil change procedure, and ensure the new hydraulic oil is compatible with the system's seals and materials.

Hydraulic Oil Selection Flowchart

Viscosity Grade Recommendations

Key Handling Tips

- Store hydraulic oil away from direct sunlight

- Keep containers tightly sealed when not in use

- Use dedicated equipment for each type of hydraulic oil

- Filter hydraulic oil when transferring to equipment

- Check expiration dates before use

Common Contaminants

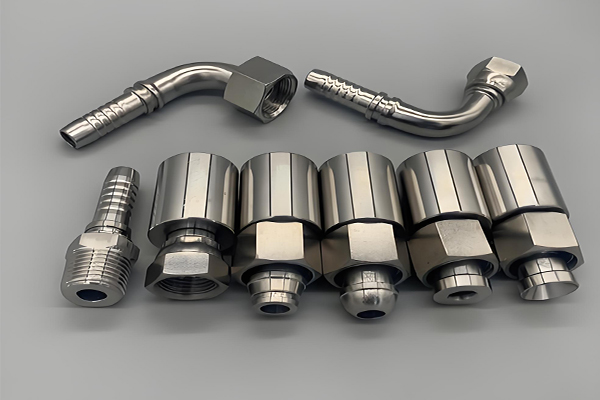

Filtration System Components

- Return Line Filters: Remove contaminants before hydraulic oil returns to reservoir

- Suction Filters: Protect pumps from large contaminants

- Pressure Filters: Protect sensitive components downstream

- Breather Filters: Prevent contamination through reservoir vents

Contamination Testing Methods

-

Particle Count Analysis

Measures and counts solid particles by size distribution

-

Karl Fischer Titration

Determines water content in hydraulic oil

-

Ferrographic Analysis

Examines wear particles to identify component issues

-

Visual Inspection

Simple check for color, clarity, and sediment

Contamination is the primary cause of hydraulic system failure and reduced hydraulic oil performance, alongside safety concerns like is hydraulic fluid flammable. Even small particles can cause significant damage to precision components, leading to increased maintenance costs, downtime, and potential safety hazards. Implementing effective contamination control measures is therefore critical for any hydraulic system.

Types and Sources of Contamination

Solid particle contamination is the most common and destructive form of contamination in hydraulic oil. These particles can originate from multiple sources: manufacturing residues left in new systems, wear particles generated by moving components, environmental contaminants entering through breather vents or worn seals, and particles introduced during maintenance procedures.

Water contamination is another significant issue, particularly in outdoor or high-humidity environments. Water can enter hydraulic oil through condensation, leaks, or washing procedures. Even small amounts of water can cause significant problems, including reduced lubricity, increased oxidation rates, additive depletion, and corrosion of metal components.

Air contamination, often in the form of entrained bubbles or dissolved air, can also compromise hydraulic oil performance. Air can enter the system through leaks in suction lines, improper filling procedures, or excessive turbulence. Aerated hydraulic oil causes cavitation, reduced system efficiency, and accelerated oil degradation.

Chemical contamination occurs when incompatible substances mix with hydraulic oil. This can happen through cross-contamination during refilling, introduction of cleaning solvents during maintenance, or leakage of other fluids into the hydraulic system. Chemical contamination often leads to viscosity changes, additive breakdown, and seal degradation.

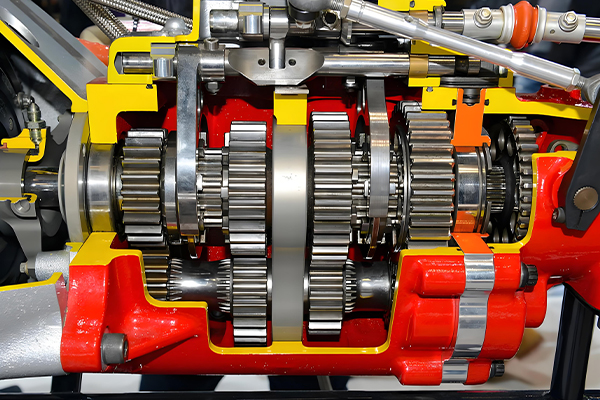

Effects of Contaminated Hydraulic Oil

The impact of contaminated hydraulic oil on system performance and component life is profound. Solid particles cause abrasive wear on pumps, valves, and cylinders, increasing clearances and reducing efficiency. In severe cases, this can lead to catastrophic component failure.

Water contamination accelerates the oxidation process of hydraulic oil, leading to the formation of sludge and varnish deposits. These deposits can clog filters, restrict flow passages, and interfere with valve operation. Water also promotes corrosion of metal surfaces, particularly in areas with high mechanical stress.

Air contamination in hydraulic oil reduces the effective bulk modulus of the fluid, leading to spongy system response and reduced control precision. The collapse of air bubbles can cause cavitation erosion on pump components, characterized by pitting and material removal from metal surfaces.

Over time, contaminated hydraulic oil loses its ability to properly lubricate and protect system components, leading to increased friction, higher operating temperatures, and a cycle of accelerated wear and contamination. This cycle ultimately results in increased maintenance costs, reduced equipment availability, and potentially dangerous system failures.

Filtration and Purification Systems

Implementing a comprehensive filtration strategy is essential for maintaining clean hydraulic oil. The filtration system should be designed to remove contaminants before they can cause damage to critical components. This typically involves multiple filtration points throughout the hydraulic system, each serving a specific purpose.

Return line filters are particularly important as they capture contaminants generated within the system before the hydraulic oil returns to the reservoir. These filters should be sized for the maximum flow rate and specified with an appropriate micron rating based on system sensitivity. Beta ratio ratings (βx(c)) provide a standardized way to compare filter performance, representing the ratio of particles greater than size x entering the filter to those exiting.

For systems operating in particularly harsh environments or those with high contamination sensitivity, offline filtration systems (kidney loop systems) can provide continuous purification of hydraulic oil. These systems circulate oil from the reservoir through high-efficiency filters, maintaining oil cleanliness even during system operation.

Water removal systems may be necessary in applications where water contamination is a persistent problem. These can include coalescing filters for free water removal and vacuum dehydration systems capable of removing dissolved water from hydraulic oil. Regular monitoring of water content is essential to determine when these systems should be utilized.

Preventive Maintenance Practices

Effective contamination control extends beyond filtration to include comprehensive preventive maintenance practices. Establishing a regular oil sampling and analysis program is fundamental, providing early warning of contamination issues before they lead to system damage.

Proper maintenance procedures are critical to preventing contamination introduction. This includes thorough cleaning of all components before installation, using clean tools and equipment during maintenance, and ensuring that any opened system ports are promptly sealed after service.

Regular inspection and replacement of seals, gaskets, and O-rings prevent environmental contamination from entering the system. Breather vents should be equipped with appropriate filters and replaced regularly to prevent dust and moisture ingress.

Training maintenance personnel in proper contamination control techniques is equally important. This includes proper handling and storage of hydraulic oil, correct filter replacement procedures, and awareness of contamination sources and prevention methods.

Contamination Monitoring Programs

Implementing a structured contamination monitoring program allows for proactive management of hydraulic oil cleanliness. This program should establish target cleanliness levels based on system requirements, typically following ISO 4406 or NAS 1638 standards.

Regular oil sampling should be conducted using proper techniques to ensure representative samples. Samples should be analyzed for particle count, water content, and other key parameters. The frequency of sampling should be based on system criticality, operating conditions, and historical data.

Monitoring data should be tracked over time to identify trends and develop predictive maintenance schedules. This data can also be used to evaluate the effectiveness of contamination control measures and make adjustments as needed.

In addition to laboratory analysis, on-site testing equipment can provide immediate results for critical parameters, allowing for rapid response to contamination issues. This includes portable particle counters, water content meters, and visual inspection tools.

Real-world applications demonstrate the practical implementation of hydraulic oil maintenance principles—such as for seastar hydraulic steering fluid—across various industries. These examples illustrate how proper hydraulic oil management can improve performance, reduce costs, and extend equipment life in specific operational contexts.

Construction Equipment Maintenance Program

A large construction company operating a fleet of 50+ hydraulic excavators, bulldozers, and cranes implemented a comprehensive hydraulic oil management program that resulted in a 35% reduction in hydraulic system failures and a 28% decrease in maintenance costs over two years.

The program began with standardizing on a single high-performance hydraulic oil formulation suitable for all equipment, simplifying inventory management and eliminating cross-contamination risks. The selected hydraulic oil featured enhanced anti-wear additives and improved oxidation resistance to withstand the wide temperature variations encountered on job sites.

A scheduled sampling program was implemented, with hydraulic oil analysis conducted every 250 operating hours. Samples were tested for particle count, viscosity, water content, and additive levels. Based on analysis results, oil changes were performed only when necessary, rather than on fixed intervals, extending average oil life from 1,500 to 2,800 hours.

The company also upgraded filtration systems on all equipment to 10-micron absolute filters with water-removal capabilities. A preventive maintenance schedule was established for filter replacements, and breather filters were checked daily as part of equipment inspections.

Training sessions were conducted for equipment operators to recognize signs of hydraulic system issues, such as unusual noises, slow operation, or temperature increases. Operators were instructed to report these issues immediately to prevent minor problems from escalating into major failures.

The program's success was attributed to the combination of proper hydraulic oil selection, condition-based maintenance, enhanced filtration, and operator awareness. The company estimated annual savings of over $400,000 from reduced downtime, fewer component replacements, and extended hydraulic oil life.

Hydraulic System Optimization in Automotive Manufacturing

An automotive manufacturing plant with over 100 hydraulic presses and robotic systems faced chronic issues with hydraulic system reliability, particularly in their stamping department. Production line stoppages due to hydraulic failures were costing an estimated $25,000 per hour in lost production.

A detailed analysis revealed that contamination levels in the hydraulic oil exceeded recommended limits by a factor of 10 or more in many systems. The root causes included inadequate filtration, improper maintenance procedures, and cross-contamination during oil changes.

The plant implemented a multi-phase improvement program starting with a complete system flush and hydraulic oil replacement using a high-performance anti-wear hydraulic oil specifically formulated for high-pressure industrial applications. All filters were upgraded to 3-micron absolute rating with differential pressure monitoring to indicate when replacement was needed.

A centralized hydraulic oil management system was installed, featuring dedicated storage tanks, filtration during transfer, and barcode tracking of all hydraulic oil movements. This eliminated cross-contamination and ensured proper oil selection for each system.

Online particle counters were installed on critical systems, providing real-time contamination monitoring and automatic alerts when cleanliness levels exceeded established thresholds. This allowed maintenance teams to address issues before they caused equipment failure.

The maintenance team also implemented a scheduled preventive maintenance program that included regular inspection of seals, hoses, and connections to prevent external contamination. All maintenance personnel received specialized training in hydraulic system best practices.

Within six months of implementing these measures, hydraulic system failures were reduced by 78%, and mean time between failures (MTBF) increased from 45 days to 187 days. The plant realized annual savings of over $2.3 million through reduced downtime and maintenance costs, while also extending the service life of hydraulic components by an average of 300%.

Hydraulic Oil Management in Agricultural Equipment

A large agricultural operation with a diverse fleet of tractors, combines, and specialized equipment faced seasonal challenges with hydraulic system performance, particularly during the demanding harvest period when equipment reliability was critical.

The operation's maintenance team noticed a pattern of increased hydraulic failures during transition periods between seasons, coinciding with significant temperature changes. Analysis revealed that the hydraulic oil viscosity was not properly matched to seasonal temperature variations, leading to inefficient operation in cold conditions and accelerated degradation in high temperatures.

To address this issue, the operation implemented a seasonal hydraulic oil change program using two different formulations: a lower viscosity hydraulic oil for winter months to ensure proper cold-start performance and a higher viscosity oil for summer operations to maintain adequate film strength at elevated temperatures.

They also established a pre-season maintenance protocol that included complete system inspection, filter replacement, and hydraulic oil analysis. This allowed potential issues to be addressed before the critical operating seasons began.

Given the dusty environment typical in agricultural operations, the maintenance team upgraded all hydraulic system breathers to high-efficiency units with hydrophobic properties to prevent both particle and moisture contamination. They also implemented a daily visual inspection program for hydraulic oil levels and signs of leaks.

To minimize downtime during the busy harvest season, the operation created a mobile maintenance unit equipped with hydraulic oil testing equipment, filtration systems, and replacement components. This allowed for on-site analysis and maintenance, reducing equipment downtime significantly.

Operator training was enhanced to include proper warm-up procedures for hydraulic systems in cold weather and recognition of early warning signs of hydraulic issues. Operators were also trained to minimize exposure of hydraulic components to dirt and debris during field operations.

These measures resulted in a 62% reduction in seasonal hydraulic failures, allowing the operation to complete harvests an average of 5 days earlier. Equipment resale values increased due to better-maintained hydraulic systems, and overall hydraulic oil consumption decreased by 18% through more efficient usage and extended change intervals.

Performance Comparison: Traditional vs. Optimized Hydraulic Oil Maintenance

Key Lessons from Real-World Applications

Condition-Based Approach

All successful programs replaced fixed-interval oil changes with condition-based maintenance using oil analysis, significantly extending hydraulic oil life while improving reliability.

Comprehensive Filtration

Upgrading filtration systems consistently resulted in dramatic reductions in contamination levels and corresponding decreases in component wear and failure rates.

Proper Product Selection

Matching hydraulic oil properties to specific operating conditions and equipment requirements proved critical to maximizing performance and extending service life.