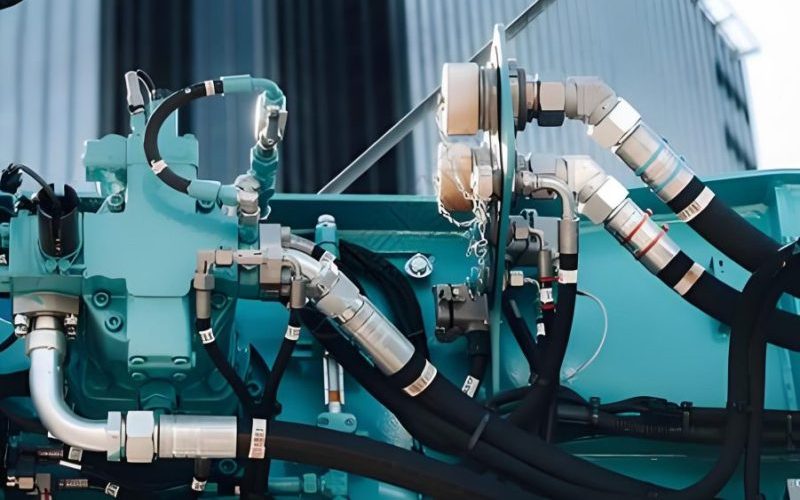

A hydraulic system is a power transmission system that uses pressurized fluid to transmit energy from one point to another. These systems are widely used in various industries due to their ability to generate large forces and precise movements. The fundamental principle behind any hydraulic system is Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to all portions of the fluid and the walls of its container.

This comprehensive guide explores the classification, working principles, components, and applications of hydraulic systems, providing a thorough understanding of how these powerful systems operate and where they are utilized across different industries.

Classification of Hydraulic Systems

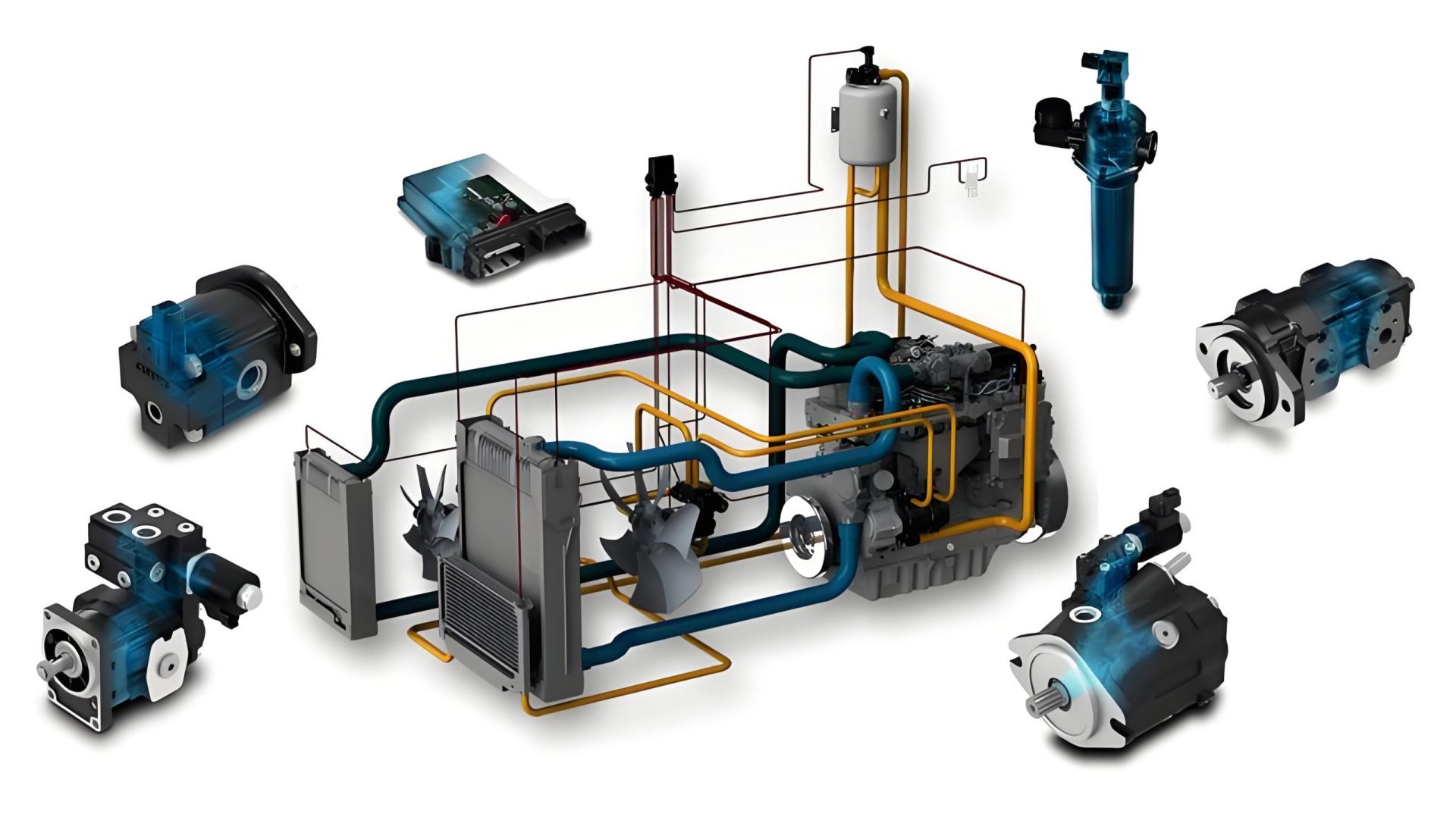

Hydraulic systems can be classified based on several criteria, including their operational principles, fluid medium, and application requirements. Understanding these classifications helps in selecting the right hydraulic system for specific industrial needs.Where can hydraulic systems be found?

By Operational Principle

- Open Loop Hydraulic Systems: In this type of hydraulic system, the fluid flows from the pump to the actuator and then returns to a reservoir, where it is stored until reused. These systems are simpler and less expensive but generally less efficient.

- Closed Loop Hydraulic Systems: These systems recirculate the fluid without returning it to a reservoir, making them more efficient. They typically include a variable displacement pump and are used in applications requiring precise control.

By Fluid Type

- Petroleum-based Hydraulic Systems: The most common type, using mineral oil as the working fluid. These systems offer good lubrication properties and are widely available.

- Water-based Hydraulic Systems: Used in applications where fire resistance is critical, such as in mining or steel production. These systems use water-glycol mixtures or other water-based fluids.

- Synthetic Hydraulic Fluids: Designed for extreme temperature conditions or specific industrial requirements where conventional fluids would fail.

By Application

- Mobile Hydraulic Systems: Found in construction equipment, agricultural machinery, and vehicles. These systems are designed to be compact and durable.

- Industrial Hydraulic Systems: Used in manufacturing machinery, presses, and factory automation. They prioritize precision and control.

- Aerospace Hydraulic Systems: Designed for lightweight construction and high reliability in aircraft and spacecraft applications.

Each classification of hydraulic system offers distinct advantages depending on the operational requirements, environmental conditions, and performance expectations of the application.

Classification of hydraulic systems based on operational principles

Mobile vs. industrial hydraulic system configurations

Working Principles and Characteristics of Hydraulic Transmission

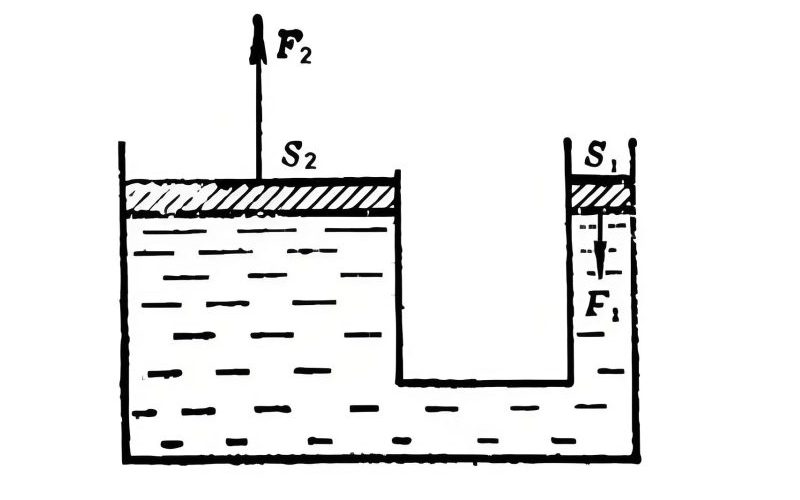

The fundamental working principle of any hydraulic system is based on Pascal's Law, formulated by Blaise Pascal in the 17th century. This law states that pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid.What is hydraulics?

Pascal's Law in Action

In a hydraulic system, when force is applied to a small piston, it creates pressure in the fluid. This pressure is transmitted undiminished to a larger piston, resulting in a larger output force. The relationship between force, pressure, and area is defined by the formula:

Pressure (P) = Force (F) / Area (A)

Which can be rearranged to: Force (F) = Pressure (P) × Area (A)

This principle allows a hydraulic system to multiply force, making it possible to lift heavy loads or generate powerful movements with relatively small input forces.

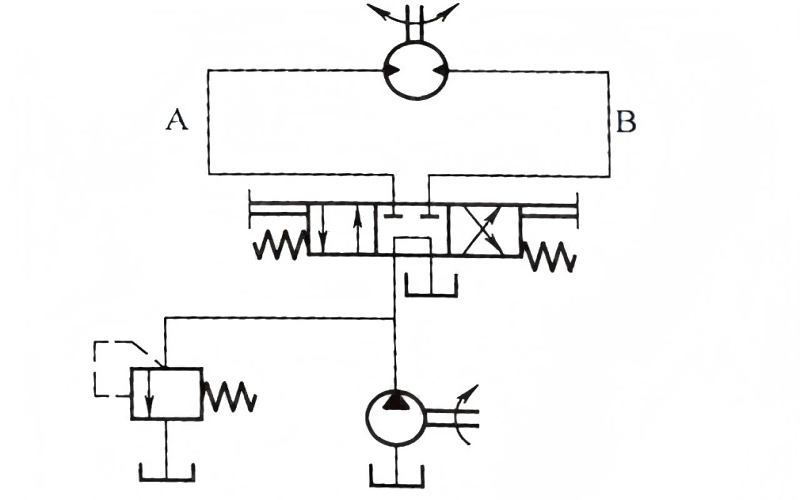

Operational Sequence

-

Energy Conversion: A hydraulic pump converts mechanical energy (typically from an electric motor or engine) into hydraulic energy (pressurized fluid).

-

Fluid Transmission: The pressurized fluid is transmitted through hoses, pipes, or tubes to hydraulic actuators.

-

Energy Conversion: Hydraulic actuators (cylinders or motors) convert the hydraulic energy back into mechanical energy, producing linear or rotational motion.

-

Control and Regulation: Valves control the direction, pressure, and flow rate of the fluid within the hydraulic system.

-

Fluid Return: The fluid returns to a reservoir, where it is filtered, cooled, and recirculated through the system.

Key Characteristics

High Power Density

Hydraulic systems provide high force and power in a compact design compared to mechanical or electrical systems.

Precise Control

A hydraulic system offers precise control over speed, force, and position, making it suitable for applications requiring accuracy.

Flexible Power Transmission

Hydraulic lines can transmit power over long distances and around obstacles more easily than mechanical linkages.

Overload Protection

Pressure relief valves in a hydraulic system provide inherent overload protection, preventing damage to components.

Smooth Operation

Hydraulic systems offer smooth acceleration and deceleration, reducing shock loads on machinery.

Power Amplification

As per Pascal's principle, a hydraulic system can multiply force, enabling small inputs to generate large outputs.

Illustration of Pascal's Law demonstrating force multiplication in a hydraulic system

Hydraulic Transmission Process

Working Medium of Hydraulic Transmission

The working medium, or hydraulic fluid, is a critical component of any hydraulic system. It serves multiple functions beyond just transmitting power, including lubricating components, dissipating heat, and preventing corrosion. The selection of an appropriate hydraulic fluid is essential for the efficient and reliable operation of the hydraulic system.hydraulic fluids.

Functions of Hydraulic Fluid

Power Transmission

The primary function is to transmit power within the hydraulic system by transferring pressure from the pump to actuators.

Lubrication

Hydraulic fluid reduces friction between moving parts, minimizing wear and extending component life.

Heat Transfer

Fluid carries heat away from components, helping to regulate the operating temperature of the hydraulic system.

Contamination Control

Fluid carries contaminants to filters where they can be removed, protecting sensitive components.

Sealing

Hydraulic fluid helps maintain the integrity of seals, preventing leaks in the hydraulic system.

Corrosion Protection

Additives in hydraulic fluids protect metal components from rust and corrosion.

Types of Hydraulic Fluids

Mineral Oil-based Fluids

The most common type used in industrial hydraulic system applications, offering:

- Good lubrication properties

- Wide operating temperature range

- Compatibility with most system materials

- Cost-effectiveness

- Good availability

These fluids are derived from petroleum and are suitable for general-purpose hydraulic applications.

Water-based Fluids

Used in applications where fire resistance is critical:

- High fire resistance

- Good heat dissipation

- Lower cost than synthetic fluids

Common formulations include water-glycol mixtures and water-in-oil emulsions, suitable for steel mills, foundries, and mining operations where a hydraulic system might be exposed to high temperatures or open flames.

Synthetic Fluids

Man-made fluids designed for specific performance characteristics:

- Extreme temperature stability

- Enhanced oxidation resistance

- Superior lubricity

- Compatibility with specialized materials

These fluids are used in specialized applications such as aerospace, cold climates, or high-temperature environments where a standard hydraulic system fluid would fail.

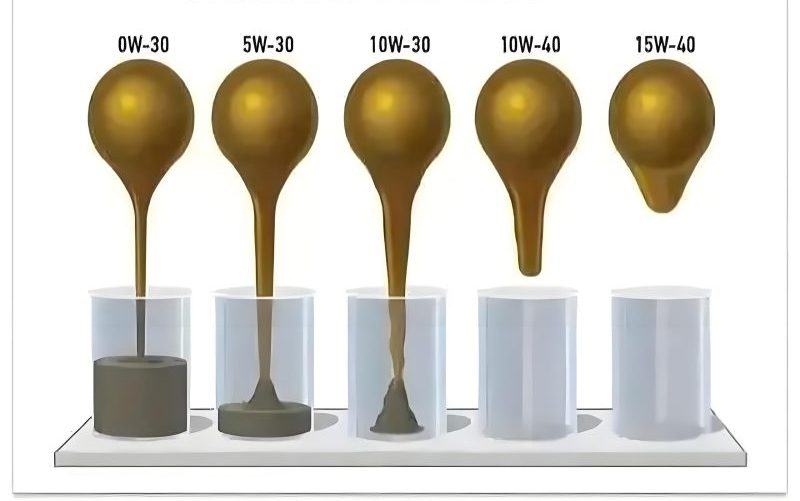

Key Properties of Hydraulic Fluids

Viscosity

A measure of a fluid's resistance to flow. Proper viscosity ensures efficient operation of the hydraulic system across the operating temperature range.

Viscosity Index

Indicates how much the viscosity changes with temperature. Higher values mean more stable viscosity in varying temperatures.

Pour Point

The lowest temperature at which the fluid will still flow, important for hydraulic system operation in cold environments.

Flash Point

The temperature at which the fluid produces enough vapor to ignite, critical for safety in high-temperature applications.

Oxidation Stability

Resistance to chemical breakdown when exposed to oxygen, affecting the fluid's service life in a hydraulic system.

Demulsibility

The ability to separate from water, important for preventing corrosion and maintaining performance.

Various types of hydraulic fluids used in hydraulic systems

Hydraulic Fluid Performance Comparison

Fluid Selection Criteria

- Operating temperature range of the hydraulic system

- System pressure and flow requirements

- Compatibility with system materials

- Environmental conditions and regulations

- Fire safety requirements

- Maintenance considerations and service life

Advantages, Disadvantages and Applications of Hydraulic Transmission

To fully evaluate hydraulic transmission—including its suitability for specific applications—it is first critical to understand the advantages of hydraulic energy, as these inherent energy characteristics (e.g., ability to transmit high force with compact components, stable operation under heavy loads) form the basis of hydraulic transmission’s own advantages. Like any technology, hydraulic transmission offers distinct advantages and disadvantages that determine its suitability for specific applications. Understanding these (both energy-derived strengths and transmission-specific limitations) helps engineers select the optimal power transmission system, whether a hydraulic system or an alternative like mechanical or electrical transmission.

Advantages

- High Power Density: A hydraulic system can generate significant force and power in a compact size compared to mechanical or electrical systems.

- Precise Control: Hydraulic systems offer exceptional control over speed, position, and force, enabling fine adjustments.

- Force Multiplication: As per Pascal's principle, small input forces can generate large output forces in a hydraulic system.

- Flexible Layout: Hydraulic lines can transmit power around obstacles and over distances more easily than mechanical linkages.

- Shock Absorption: Hydraulic systems can absorb shock loads, protecting machinery from damage.

- Overload Protection: Pressure relief valves in a hydraulic system prevent damage during overload conditions.

- Simultaneous Operation: A single hydraulic system can power multiple actuators with different functions simultaneously.

Disadvantages

- Fluid Leaks: A hydraulic system is susceptible to fluid leaks, causing inefficiency and environmental concerns.

- Maintenance Requirements: Regular maintenance is needed to prevent contamination and ensure proper functioning.

- Fluid Compressibility: Under extreme pressures, fluid compression can affect hydraulic system precision.

- Temperature Sensitivity: Hydraulic fluid viscosity changes with temperature, affecting system performance.

- Noise Levels: Hydraulic pumps and valves can generate significant noise in a hydraulic system.

- Environmental Impact: Hydraulic fluid spills can contaminate soil and water sources.

- Initial Cost: The components of a hydraulic system can be more expensive than mechanical alternatives.

Major Applications

Heavy Machinery

Almost all modern construction equipment utilizes hydraulic system technology. Excavators, bulldozers, cranes, loaders, and backhoes rely on hydraulic cylinders and motors for their primary functions. The high power density and precise control of a hydraulic system make it ideal for these applications where heavy loads must be moved with accuracy.

Farming Equipment

Agricultural machinery such as tractors, combines, and harvesters use hydraulic system components for various functions including lifting implements, steering, and operating attachments. The versatility of a hydraulic system allows farmers to use a single tractor with multiple hydraulic attachments for different tasks throughout the growing season.

Industrial Processes

The manufacturing sector extensively uses hydraulic system technology in presses, injection molding machines, material handling equipment, and automated production lines. Hydraulic presses can generate the high forces needed for metal forming, stamping, and assembly operations. The precise control offered by a hydraulic system ensures consistent product quality in mass production environments.

Aircraft Systems

Aircraft rely on lightweight, high-performance hydraulic system components for critical functions including landing gear operation, flight control surfaces, and braking systems. The reliability and power-to-weight ratio of a hydraulic system make it indispensable in aviation, where safety and performance are paramount. Modern aircraft often feature multiple redundant hydraulic systems for enhanced safety.

Ship and Offshore Systems

Ships and offshore platforms use hydraulic system technology for steering, cargo handling, winches, and deck machinery. The ability of a hydraulic system to operate reliably in harsh marine environments, including resistance to corrosion and contamination, makes it well-suited for these applications. Hydraulic systems also provide the precise control needed for docking and maneuvering large vessels.

Wide range of applications for hydraulic systems across different industries

Industry Adoption of Hydraulic Systems

Key Considerations for Hydraulic System Implementation

-

System Design

Proper hydraulic system design must account for pressure requirements, flow rates, and component sizing.

-

Fluid Selection

Choosing the right hydraulic fluid is critical for hydraulic system performance and longevity.

-

Maintenance Planning

Regular maintenance schedules prevent hydraulic system failures and extend service life.

-

Environmental Factors

Temperature, humidity, and contamination risks must be addressed in hydraulic system implementation.

Working Principle of Hydraulic Control Systems

A hydraulic control system is an advanced type of hydraulic system designed to automatically regulate and control the operation of hydraulic components based on specific input signals or conditions. Unlike basic hydraulic systems that simply transmit power, control systems incorporate feedback mechanisms to maintain desired operating parameters, making them highly precise and adaptable.

The core principle of a hydraulic control system is to compare a desired output (setpoint) with the actual output, then adjust the hydraulic system operation to minimize any difference (error) between them. This closed-loop operation—enabled by hydraulic controls that monitor output signals, transmit adjustment instructions, and regulate hydraulic parameters in real time—allows for precise control even when external conditions or loads change.

Basic Control Loop Operation

-

Setpoint Input: An operator or automated system sets a desired parameter (position, pressure, flow, or speed) for the hydraulic system.

-

Sensing: Transducers or sensors measure the actual operating parameter of the hydraulic system.

-

Comparison: A controller compares the actual value with the setpoint, calculating the error between them.

-

Control Action: The controller generates a corrective signal based on the error.

-

Actuation: Hydraulic components (typically servovalves or proportional valves) adjust the hydraulic system operation to correct the error.

-

Feedback: The process continuously repeats, with the sensor providing updated information to the controller.

Types of Hydraulic Control Systems

Open-Loop Control Systems

In an open-loop hydraulic control system, there is no feedback mechanism. The control action is determined solely by the input signal, without reference to the actual output. While simpler and less expensive, open-loop systems cannot compensate for external disturbances or changes in load. They are used in applications where precision is not critical and operating conditions remain relatively constant.

A basic example is a simple hydraulic jack, where the operator controls the hydraulic system directly without automated feedback.

Closed-Loop (Feedback) Control Systems

Closed-loop systems incorporate feedback to continuously adjust the hydraulic system operation. This allows them to maintain precise control even when faced with varying loads, temperatures, or other disturbances. The feedback loop creates a self-correcting mechanism that significantly improves accuracy and stability.

Examples include hydraulic position control systems in manufacturing machinery and speed control systems in industrial drives. The additional complexity of a closed-loop hydraulic system is offset by its superior performance in applications requiring precision.

Control Modes in Hydraulic Systems

Proportional Control

The control action is proportional to the error signal. A hydraulic system using proportional control provides a corrective action that increases as the error between setpoint and actual value increases.

Integral Control

This control mode responds to the cumulative error over time, eliminating steady-state errors in the hydraulic system. Integral control is often combined with proportional control for better performance.

Derivative Control

Derivative control responds to the rate of change of the error, providing damping and stability to the hydraulic system. It helps prevent overshoot and oscillations in the controlled parameter.

Most advanced hydraulic control systems use a combination of these modes, known as PID (Proportional-Integral-Derivative) control, to optimize the performance of the hydraulic system across various operating conditions.

Dynamic Response Characteristics

The performance of a hydraulic control system is evaluated by its dynamic response to changes in setpoint or load. Key characteristics include:

- Rise Time: The time required for the hydraulic system to reach the desired setpoint from a resting state.

- Settling Time: The time required for oscillations to dampen and the system to stabilize at the setpoint.

- Overshoot: The amount by which the system exceeds the setpoint before stabilizing.

- Steady-State Error: The small difference between the setpoint and actual value after the system stabilizes.

- Bandwidth: The range of frequencies at which the hydraulic system can effectively respond to input changes.

These characteristics are influenced by the design of the hydraulic components, the control algorithm, and the mechanical properties of the load being controlled.

Closed-loop hydraulic control system with feedback mechanism

Hydraulic Control System Response

Key Performance Parameters

Typical performance parameters for a high-precision hydraulic control system

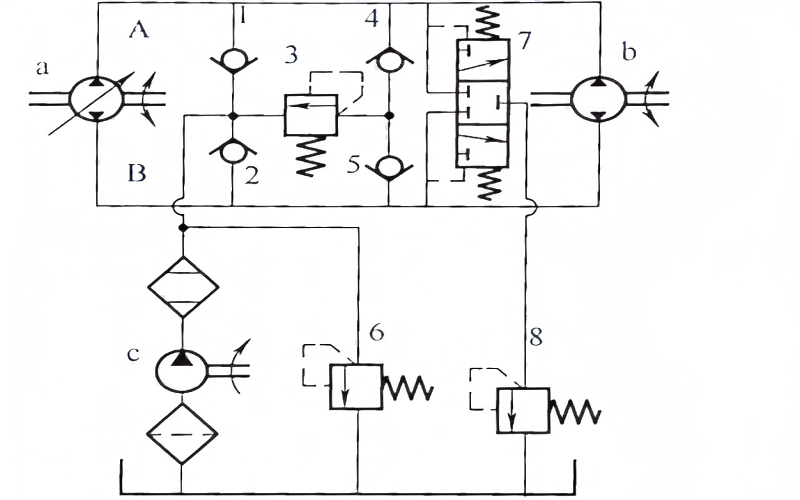

Composition and Characteristics of Hydraulic Control Systems

A hydraulic control system is a sophisticated integration of mechanical, hydraulic, and often electronic components working together to provide precise control of force, speed, position, or pressure. These systems build upon the basic components of a standard hydraulic systems by adding specialized control elements that enable automated operation and feedback.

Major Components of Hydraulic Control Systems

Power Supply Unit

This forms the heart of the hydraulic system, consisting of:

- Hydraulic Pump: Converts mechanical energy to hydraulic energy

- Electric Motor or Engine: Drives the hydraulic pump

- Reservoir: Stores hydraulic fluid and helps with cooling

- Filters: Remove contaminants from the fluid

- Cooler: Maintains optimal operating temperature

The power supply unit ensures a consistent flow of clean, cooled fluid at the required pressure for the hydraulic system operation.

Control Valves

These are critical components that regulate fluid flow, pressure, and direction in the hydraulic system:

- Servovalves: Provide precise flow control in response to electrical input signals

- Proportional Valves: Offer proportional control of flow or pressure based on input signals

- Pressure Control Valves: Maintain system pressure within safe operating limits

- Directional Control Valves: Control the direction of fluid flow to actuators

Modern control valves often incorporate electronic interfaces, allowing seamless integration of the hydraulic system with digital control systems.

Actuators

These components convert hydraulic energy back into mechanical motion in the hydraulic system:

- Hydraulic Cylinders: Produce linear motion through extension and retraction

- Hydraulic Motors: Generate rotational motion at various speeds and torques

- Rotary Actuators: Provide limited-angle rotational movement

Actuators in control systems are often designed with precision mounting surfaces to facilitate accurate position sensing and alignment.

Sensors and Transducers

These devices provide feedback for the closed-loop operation of the hydraulic system:

- Position Sensors: Measure linear or rotational position of actuators

- Pressure Transducers: Monitor system pressure at critical points

- Flow Meters: Measure fluid flow rates within the system

- Temperature Sensors: Monitor fluid temperature

- Force/Torque Sensors: Measure output forces or torques

These sensors convert physical parameters into electrical signals that can be processed by the control system, enabling precise monitoring and adjustment of hydraulic system performance.

Controller

The brain of the hydraulic control system, responsible for:

- Receiving input signals from sensors and operators

- Processing information using control algorithms

- Generating output signals to control valves

- Providing interface for operator input and monitoring

Modern controllers often use microprocessors with sophisticated software that can be programmed with PID or other advanced control algorithms to optimize hydraulic system performance.

Auxiliary Components

Various components that support the operation of the hydraulic system:

- Pipes and Hoses: Transmit fluid between components

- Fittings and Connectors: Join hydraulic lines

- Seals and Gaskets: Prevent fluid leakage

- Accumulators: Store hydraulic energy and dampen pressure fluctuations

- Manifolds: Provide centralized connection points for multiple components

These components ensure the reliable and efficient operation of the entire hydraulic system, with proper sizing and selection critical for performance.

Key Characteristics of Modern Hydraulic Control Systems

High Precision

Modern systems can achieve positioning accuracy within microns, making them suitable for applications requiring extreme precision.

Fast Response

Advanced hydraulic control systems can respond to input changes in milliseconds, enabling dynamic performance.

Adaptability

Programmable controllers allow the hydraulic system to adapt to different operating conditions and requirements.

Energy Efficiency

Modern designs incorporate energy recovery and variable displacement technologies to improve efficiency.

Diagnostic Capabilities

Integrated sensors and smart controllers enable condition monitoring and predictive maintenance of the hydraulic system.

Redundancy

Critical applications feature redundant components to ensure reliability and prevent system failure.

Communication Capabilities

Modern systems can integrate with industrial networks, enabling centralized monitoring and control of multiple hydraulic system units.

Robustness

Designed to operate reliably in harsh environments with temperature extremes, vibration, and contamination risks.

The combination of these characteristics makes the modern hydraulic control system a versatile and powerful solution for numerous industrial applications, offering an optimal balance of power, precision, and flexibility that is difficult to achieve with purely mechanical or electrical systems. As technology advances, we continue to see improvements in hydraulic system efficiency, intelligence, and performance, expanding their range of applications even further.

Hydraulic Control System Block Diagram

Evolution of Hydraulic Control Systems

1950s-1960s

Simple mechanical and hydraulic control systems with basic functionality

1970s-1980s

Introduction of electro-hydraulic controls and basic feedback loops

1990s-2000s

Microprocessor-based controllers and improved sensor technology

2010s-Present

Smart hydraulic systems with IoT integration, predictive maintenance, and energy recovery