Comprehensive Hydraulic Engineering Resource

This website serves as the definitive guide to hydraulic technology, covering everything from basic principles to advanced system design, maintenance, and troubleshooting. Whether you're a student, engineer, technician, or industry professional, you'll find valuable insights and practical knowledge here.

Hydraulic Fundamentals

Hydraulics is a branch of science and engineering focused on the mechanical properties of liquids. The principles of hydraulics are based on Pascal's Law, which states that pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid such that the pressure variations (initial differences) remain the same.

Understanding these fundamentals is crucial for anyone working with hydraulic systems. They form the basis for designing, analyzing, and troubleshooting hydraulic machinery and equipment. From simple hand pumps to complex industrial systems, the principles remain the same.

Learn more about hydraulic fundamentals

"The principles of hydraulics are the backbone of modern heavy machinery and industrial automation."

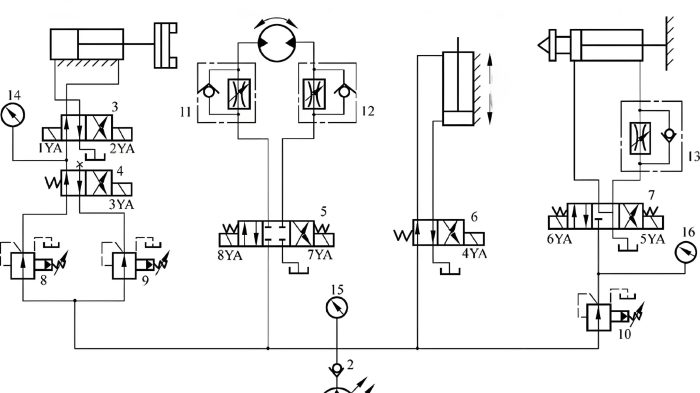

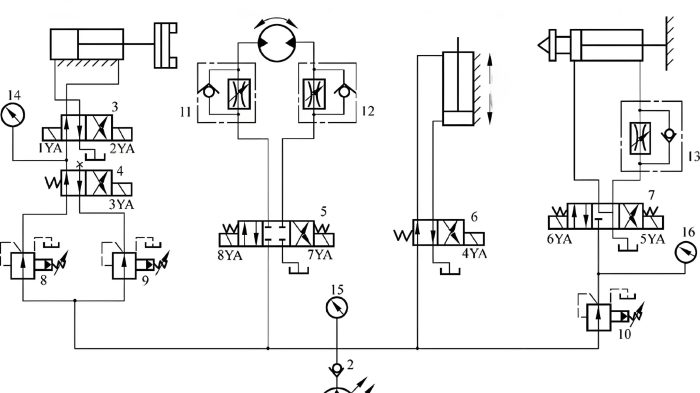

Hydraulic Diagram Reading

Hydraulic diagrams are essential tools for understanding, designing, and maintaining hydraulic systems. They use standardized symbols to represent components and their interconnections, allowing engineers and technicians to visualize how a system operates.

Mastery of hydraulic diagram reading is a critical skill for hydraulic technicians and engineers. It enables efficient communication, accurate system analysis, and effective problem-solving in both simple and complex hydraulic systems.

Explore hydraulic diagram symbols and conventionsHydraulic Fluid Maintenance

Hydraulic fluid is the lifeblood of any hydraulic system. It transfers power, lubricates components, dissipates heat, and prevents corrosion. Proper maintenance of hydraulic fluid is essential for system performance, efficiency, and longevity.

Contaminated or degraded hydraulic fluid can lead to increased wear, component failure, reduced efficiency, and costly downtime. Regular monitoring and maintenance of hydraulic fluid ensure optimal system performance and reliability.

Learn about best practices for hydraulic fluid maintenance

"Proper hydraulic fluid maintenance can extend system life by up to 50%."

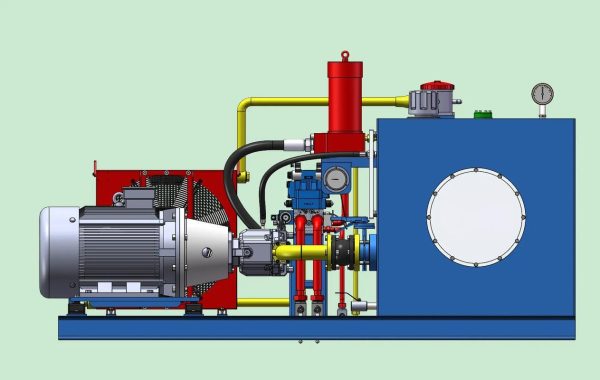

Hydraulic Pumps

Hydraulic meaning are the power source of hydraulic systems, converting mechanical energy into hydraulic energy. They generate flow to overcome pressure resistance from the load. The selection of the right pump is critical for system efficiency and performance.

Hydraulic pumps come in various types, each with unique characteristics suitable for different applications. Proper installation, operation, and maintenance of pumps are essential to ensure reliable system performance and prevent premature failure.

Explore hydraulic pump technology and applicationsHydraulic Motors

Hydraulic motors convert hydraulic energy back into mechanical energy, providing rotational motion. They are the rotational counterpart to hydraulic cylinders, which provide linear motion. Hydraulic motors are used in applications requiring high torque and variable speed.

Hydraulic motors offer several advantages over electric motors, including higher power density, better torque at low speeds, and the ability to operate in harsh environments. Proper sizing and integration with the hydraulic system are critical for optimal performance.

Learn about hydraulic motor principles and applications

"Hydraulic motors provide exceptional power-to-weight ratios, ideal for mobile equipment."

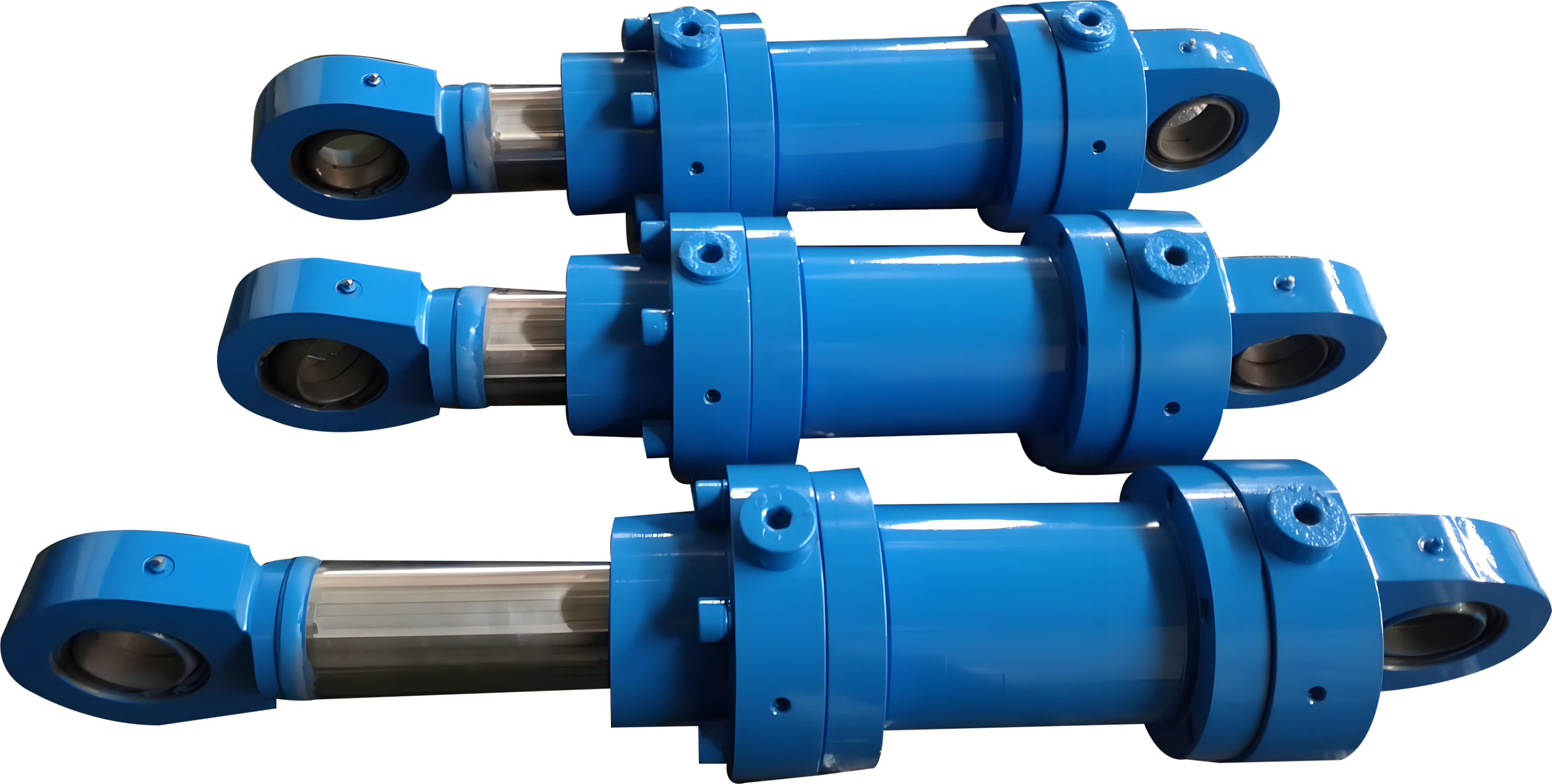

Hydraulic Cylinders

Hydraulic cylinders convert hydraulic energy into linear mechanical force and motion. They are used in a wide range of applications, from industrial machinery to mobile equipment. The design and operation of hydraulic cylinders are critical to system performance.

Proper cylinder selection, installation, and maintenance are essential to ensure reliable operation and prevent costly downtime. Factors such as load requirements, speed, stroke length, and environmental conditions must be considered when designing with hydraulic cylinders.

Explore hydraulic cylinder technology and best practicesHydraulic Valves

Hydraulic valves control the flow, pressure, and direction of hydraulic fluid in a system. They are essential components that determine how a hydraulic system operates and responds to different conditions and requirements.

The proper selection and configuration of hydraulic valves are critical for achieving the desired performance, efficiency, and safety in hydraulic systems. Advances in valve technology continue to improve system precision, responsiveness, and energy efficiency.

Learn about hydraulic valve types and applications

"Modern hydraulic valves offer precise control capabilities, enabling complex automation."

Hydraulic Auxiliary Components

Hydraulic auxiliary components play essential roles in supporting the main functions of hydraulic systems. They ensure system reliability, efficiency, and longevity by managing fluid quality, temperature, and system integrity.

Although often overlooked, auxiliary components are critical for maintaining optimal hydraulic system performance. Proper selection, installation, and maintenance of these components are essential for preventing system failures and ensuring long service life.

Explore hydraulic auxiliary component technologiesHydraulic Basic Circuits & Troubleshooting

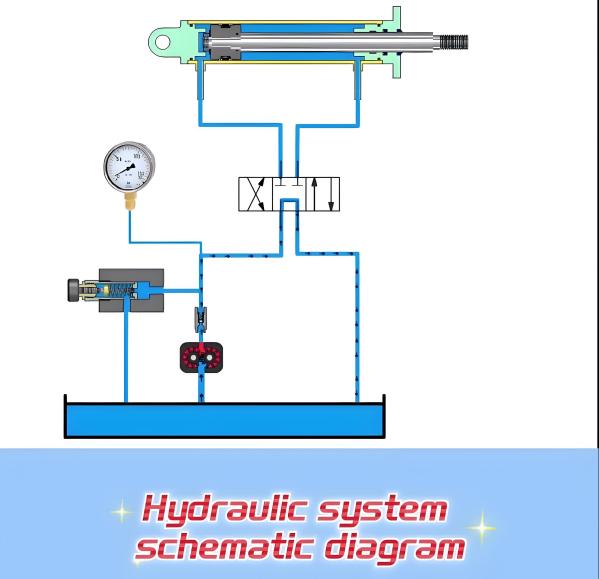

Hydraulic circuits are combinations of components that perform specific functions within a hydraulic system. Understanding basic circuits is fundamental to designing, analyzing, and troubleshooting more complex systems.

By mastering basic hydraulic circuits, engineers and technicians can design efficient systems and quickly diagnose and resolve issues. Troubleshooting skills are particularly important for minimizing downtime and maintaining productivity in industrial and mobile applications.

Learn about hydraulic circuit design and troubleshooting

"A well-designed hydraulic circuit balances performance, efficiency, and reliability."

Hydraulic System Installation & Maintenance

Proper installation and maintenance are critical for ensuring the reliable operation and longevity of hydraulic systems. Even the highest quality components will fail prematurely if not installed correctly or maintained properly.

Following industry-standard installation and maintenance practices reduces the risk of system failures, extends component life, and ensures safe operation. Regular maintenance also helps identify potential issues before they lead to costly downtime.

Discover hydraulic system installation and maintenance protocolsTypical Equipment Hydraulic Systems

Hydraulic systems are used in a wide range of equipment across various industries. Understanding the specific requirements and configurations of these systems is essential for effective design, maintenance, and troubleshooting.

Each application has unique requirements and challenges, from high-pressure systems in industrial presses to precision control in aerospace applications. Familiarity with typical equipment hydraulic systems helps in selecting appropriate components and designing efficient, reliable systems.

Explore hydraulic systems in various industries and equipment

"Hydraulics power some of the most critical machinery across industries worldwide."

Access Comprehensive Hydraulic Resources

Subscribe to our newsletter for the latest updates, technical articles, and industry insights. Join thousands of hydraulic professionals who trust our expertise.